First Things First: Once the paper weight and color is determined its time to measure and cut. Remember, this is a handmade establishment. There are no machines programmed to cut out each piece of paper (at least there are no machines other than me).

For this order two sheets of paper were used to achieve the desired look which means twice the cutting. A mint green 80lb cover weight paper (medium weight cardstock) served as the background while the text was printed on a white 80lb cover weight paper. The text sheets were all cut slightly smaller than the green to create an even border of color around the invitation, but that comes later.

Here you see at the left the paper I start out with measures 8 1/2" x 11". It must be cut on the sides to measure 4" in width. The length is not yet cut.

Each piece is carefully inspected. Only crisp smooth edges are allowed. See where its frayed? This whole step can be very very time consuming.

Second: Once all the background paper has been cut and inspected its time to create the detailed lace work edging for the top of the invitation. Now you can see things taking shape.

Third: I measure the width I'd like the top flap to be and use the groove from my Fiskar's paper trimmer to help me achieve an even line when I score the paper. Now that the top of the invite has been detailed and scored its safe to cut the length of the paper to 9 1/4".

It's important to make sure that each piece of paper is measured exactly the same when scoring the top flap.

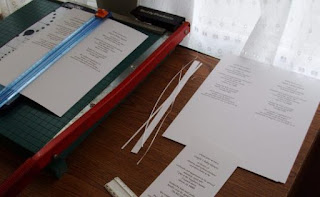

Fourth Up: After printing a test sheet on scrap paper and checking the layout its time to print the text. I chose an 8 1/2" x 11" size paper so its printer ready. Since a sheet of paper tends to have a smooth side and a slightly textured side its important to be sure to print on the same side each time when feeding the paper through the printer. This way all invitations are made using the same format.

I find that feeding one sheet of paper at a time ensures that each one is printed evenly. Yes, I use a ruler to make sure. Precision is crucial.

Fifth: More measuring and cutting; length and width wise. I pick a line of text and measure the margin from the first letter and then the last in order to assure that the text on each sheet is centered perfectly. As for the leftovers, the widest strips of paper are saved and used to bundle invitation and stationery sets. Anything else that can't be re-purposed is recycled.

Sixth: Now that all text has been printed and cut its time to add the images, in this case two little bunnies. On the scrap sheet of text that was printed earlier I experiment with the best placement of these little friends. They need to be perfectly centered. It helps to pick a specific letter from the line above and each time I'm about to stamp an image I look to align it with that particular letter.

First I stamped the boy bunny on all the invites then I went back and stamped the girl. I needed them to look like they were holding hands and stamping them separately was the only way to achieve the look.

Seventh: After each invite has been hand printed (stamped) its time to use my watercolor pencils and add some color. Once I pick up a colored pencil I use that color on each invite. For example, with the pink pencil in hand I color the dress and tint the inner ears of the bunnies on each invite, then I use the green and color the boy's shirt and the girl's flower on each invitation and so on until all is colored. It's easier than coloring one invitation at a time and picking up and setting down the pencils over and over.

Without any color these little bunnies look like nudies to me!

Eighth: After the water has been painted on and the paper dries (it shouldn't be that damp or you've used too much water) its time to assemble the invitations.

Ninth: This step involves tying lots and lots of pretty bows. Once they are all tied its time to glue them to the top of each invite and set aside to dry overnight.

So many pretty little bows!

After a good night's sleep I went to check on the invitations. The morning sun had cast such a pretty shadow on them that I had to capture it.

Tenth: My favorite part of every order is stacking all the pretty invitations, counting out the envelopes and bundling them together. There is nothing more satisfying than completing an order and getting it ready for its recipient. I always make sure to tuck a little handwritten note inside to let each client know how truly grateful I am to have been picked for the job.

Bundled with a thank you note written on my new Birdcage Cards stationery!

This little cotton tailed bunny hopped on over and went home with the invitations as a small token of thanks to a wonderful client. Hopefully it will pair perfectly with her gift to give to her friends at the bunny themed couple's baby shower she and her husband are throwing for them.

Since, this order was being hand delivered I was able to present it like a gift. Of course the wrappings had to match the invitations!

It's a Wrap:

So there you have it - a peek into the making of a set of invitations. I hope you have a better sense of what goes into completing an order. There are a lot of time consuming details, that's true, but each ensures that every invite put together is done so with precision every step of the way. This small order took two days and one night (for the adhesive on the bows to dry) to assemble and I loved every second of it.

No comments:

Post a Comment